Temperature or Process On-Off Controller

(Microcontroller based – 2 to 6 Set Points)

Mini On-Off Temperature Controller – DPC-480

View Detials

Advanced On-Off Temperature Controller – DPC-966

View Detials

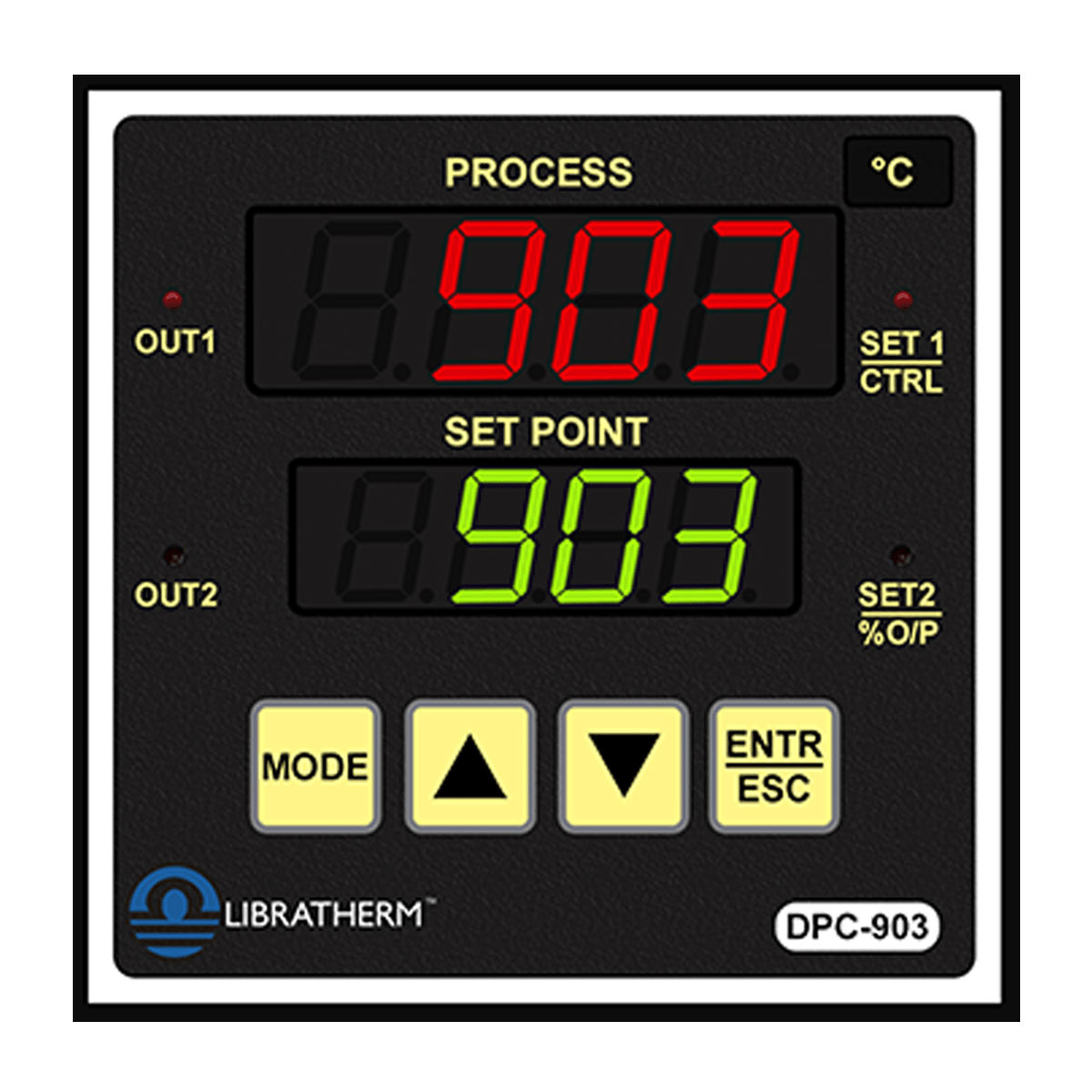

Basic On-Off Temperature Controller – DPC-903

View Detials

On-Off Temperature Controller – DPC-913

View Detials

| Model | Product Description | Size (mm.) |

| DPC-480 | Temperature and Process Controller | 48 x 48 x 120 |

| DPC-912 | Temperature and Process Controller | 96 x 48 x 75 |

| DPC-913 | Temperature and Process Controller | 48 x 96 x 75 |

| DPC-903 | Temperature and Process Controller | 96 x 96 x 75 |

| DPC-966 | Temperature and Process Controller | 96 x 96 x 120 |

Description :

Libratherm offers New version (Model HTC-723 and HTC-966) which are designed and developed using the latest micro-controller. The specification incorporated serves the every simple and critical process control applications of the industry. It accepts input from temperature sensors like thermocouple, RTD (Pt-100), Infrared thermocouple, or pyrometers generating mV or mA signals or from the level/flow/pressure/pH transmitters in the form of (4-20) mA. The input signals from thermocouples and RTD (Pt-100) are software Linearized for 1oC/0.1oC indicating accuracy. It can also be used for other process control applications like pressure control, level control etc. accepting input signals from the respective transmitter or transducers.

HTC-723 / HTC-966 accepts universal input. User can select one of 8 different types of input using back panel DIP switch. This is the added advantage over the fixed type of input.

The controller HTC-723 and HTC-966 has respectively 2 to 4 and 2 to 6 programmable set points. Each can be configured as either High Alarm or Low Alarm or Deviation Alarm or for Off state with programmable ON/OFF hysterisis through user friendly membrane key board. Dual 4 digits display allows simultaneous indications of the process value and the set value. In addition these models can give two nos. retransmission output of 4-20mA proportional to process value, for remote indication of the process value.

Features :

• Highly accurate and sturdy in operation.

• Elegant looks, Very easy to operate.

• Accepts standard type of thermocouple or RTD (Pt-100) 2 or 3-wire input

• Control output of Relay or DC pulse or TRAIC.

.• Programmable Hysterisis.

• User configurable output up to 4 or 6 set points.

• Models available in 2, 3 and 4 configurable set points

• High quality membrane keypad.

• Operates on Universal supply of 90 to 250 VAC, 50/60 Hz.

Application :

• Pressure control

• Heater bank selection

• Star delta changeover

• Level control

• Process industry

• Plastic / Packaging industry

Technical specifications :

| Input | T/C J, K, R, S, B, C, D or RTD(Pt-100) 2 or 3-wire |

| Range | Subject to the full range of the specified input |

| Resolution | 0.1/1 °C / unit subject to the specified input and range |

| Indicating Accuracy | Better than ± 1 oC / 0.1 oC /0.1 % of the specified range. |

| Control Mode | Each output is user configurable for High/Low/Deviation/Off state. |

| Control Action | ON / OFF with programmable Hysterisis |

| No. Of Set points (X) | X= 2 to 4 set points (HTC-723) ie X = 2 or 4 X= 2 to 6 set points (HTC-966) ,ie X= 2,4 or 6 |

| Control outputs | 2 or 4 DC pulses or only Two Relays or Two AC SSR in HTC-723, HTC-948 & HTC-489 . (External 4 channel relay card can be used for HTC-723, HTC-948 & HTC-489) 2 , 4 or 6 DC pulses or maximum 4 Relays or maximum 2 AC SSR in HTC-966 (External 6 channel relay card can be used for HTC-966) |

| Output and Set Point indications | Front panel LED indications OUT1 to OUT 6 for Outputs and SP1 to SP6 for set points. |

| Retransmission Signal | 2 independent 4-20mA signal proportional and linearized to PV or SV– 12 bit resolution. |

| Loop Supply | 18 - 24VDC for external Two / Three wire Transmitter (optional and available in HTC-966 only) |

| Supply | Universal supply of 90 to 250 VAC (5VA max.), 50/60Hz or 24VDC @ 500mA (optional – please contact us). |

| Optional Serial Interface | Optically isolated 2 wire RS485 in Modbus RTU protocol. (Slave mode with programmable Modbus address) |

| Operating/Storage Temperature | 0-50 oC Max. / 0-70 oC Max. @ 10-85% Rh (Non-Condensing) |

| Enclosure | ABS plastic with polycarbonate front graphic. |

* All Optional Features are Available Extra Cost

![]()