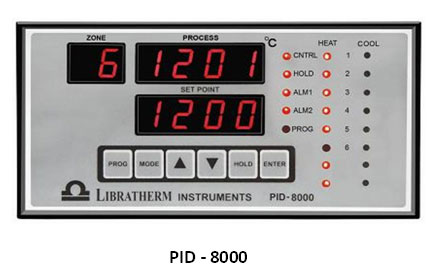

Microprocessor Based Multi-Loop PID Temperature Controller

Product Specification :

Model wise descriptions :

| Model | Description ( X = No. of loop ) |

| PID-8000-H-4 | 4 loop PID Controller for heating control |

| PID-8000-H-6 | 6 loop PID Controller for heating control |

| PID-8000-H-8 | 8 loop PID Controller for heating control |

| PID-8000-HC-4 | 4 loop PID Controller for heating and cooling control |

| PID-8000-HC-6 | 6 loop PID Controller for heating and cooling control |

| PID-8000-HC-8 | 8 loop PID Controller for heating and cooling control |

Description :

Libratherm offers Microprocessor based one to eight loop PID Temperature Controller (Model PID-8000) for processes requiring multiple zones heating or heating plus cooling control. It is most suitable for difficult process, which results in frequent system disturbances, and applications where simultaneous and accurate temperature control of number of heating/cooling zone is required. It also eliminates the need for number of individual PID or ON/OFF Temperature Controllers thereby saves on cost. PID-8000 can accept 8 similar type of Thermocouples or RTD (Pt-100) inputs and can provide switching PID or ON/OFF Control output in the form of DC Pulses or SSR Drivers for heating and cooling. It can also simultaneously provide 8 analog PID control Outputs in the form of (4-20mA) or (0-5) volt, which can be used to drive external SCR Heater Power Controller or other actuators. Open or Faulty sensor indications for each zone is also displayed with the respective Zone No. Each zone loop parameters like PID, SET, Hysterisis, Power Limit and Ramp Time values can be independently programmed from the user-friendly front panel membrane keyboard.

The display scan rate is programmable from 1 to 99 seconds, whereas the internal control scanning is at the rate of 100mS. It also provides common High and Low alarm relay outputs, which can be used for external temperature dependent, inter locking or audio-visual alarms. In brief, PID-8000 is as good as 8 independent PID controllers in a single enclosure, with facility of different input per channel, different set point per channel and different output per channel – a unique feature.

The serial interface of RS-485 in Modbus protocol is also optionally available for computer interface. The supporting window based software allows user to monitor behavior all the heating zones in both graphical and tabular form.

Libratherm also supplies complete ready to use Temperature Control Panel using PID-8000 and other switchgear items and power controllers, which finds its applications in large heating systems

Features :

• Microprocessor based design.

• Elegant looks and Very easy to operate.

• Accepts all types of maximum 8 inputs.

• PID or ON / Off heat and cool action per channel.

• All zones are individually configurable for Heat or Cool.

• Compact in size – ½ DIN (192 x 96 x 200 mm).

• Versatile application and sturdy in operation.

• Accuracy better than ± 0.1 % of the full scale.

• RS 485 / RS 232 Serial communication available.

Application :

• Plastic extruders for pipes, sheets etc…

• Plastic injection, for runner less moulding

• Heat treatment using tunnel furnace

• Large furnace and oven for homogeneous control

• Environmental chambers

• Multi zone furnace

• Laboratory equipments etc…

Technical specifications :

| No. of Inputs | 4, 6 or 8 |

| Input types | J, K, R, S, B, C, D, RTD(PT-100), RTD(PT-1000)/2 or 3 wire, (4-20)mA, (0-5)V etc. (each channel can be of similar or different input type – user must specify at the time of ordering) |

| Range | Subject to the full range of the specified input (Refer range selection table below in PDF) |

| Indicating Accuracy | Better than ± 0.1% of the specified range (Software Linearized) |

| Resolution | 0.1/1 oC Subject to the specified range |

| Display |

4 digit 0.5” Red 7-segment LED for actual temperature 4 digit 0.5” Red 7-segment LED for set temperature 2 digit 0.5” Red 7-segments LED for zone or channel number. |

| Open or Short Sensor Indication | Display shows FLt-1 or FLt-2 and outputs will be turned OFF. |

| Tuning | Auto/Manual tuning of PID values. |

| Settings | Using front panel membrane key board to set the various values. |

| Scan Rate | 1 to 99 sec (programmable through front panel keyboard). |

| Skip/Hold | Available through key board in configuration mode. |

| Memory Backup | Retention of PID and set values in the non volatile memory in the event of power failure. |

| Alarm Outputs | 2 Extra Relay outputs used for common High and Low Alarms (Relay changeover contacts rated for 5A @ 230VAC). |

| Control Action | PID or ON/OFF selectable (for both Heating and Cooling control action). |

| Control Output | DC Pulse, (4-20)mA, (0-5)VDC output per zone with soft ramp start (rt) and power limit (PL) facility for analog output. |

| Digital Interface | Parallel Centronics printer output port for Printer interface and Serial (RS232 or RS485 on Modbus ASCII) for PC interface with Window based software. |

| Supply | 230VAC / 110 VAC ± 10% (10VA), 50/60Hz |

| Size | 192 x 96 x 200 mm |

| Panel Cutout | 188 x 92 mm ± 0.5 mm |

![]()