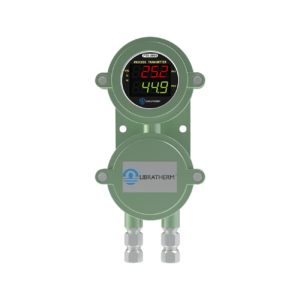

Process Transmitter With RS-485 Interface (Model PTX-3000)

FTX-3000

Product Specification :

Model wise descriptions :

| Model | Products Description | Size (mm.) |

| FTX-3000 | Process Transmitter – with single universal input (standard user selectable inputs) with single 4-20mA / 0-10V retransmission output and RS-485 interface in FLP enclosure. | 250 h x 150 w x 70 d mm. |

Description :

Libratherm offers micro-controller based Process Transmitter model FTX-300 for measuring and transmitting the analogue and digital values proportional to the Process Input. This model can accept eight industrial standard universal inputs, which is user selectable using internal DIP switch. For input selection, three options are available, where user can specify the desired model for a) universal input or b) any of the two fixed inputs or c) any of the single fixed input. Temperature or Process values corresponding to the input is indicated on the display and the corresponding display range is converted to the 2 wire isolated current output of 4-20mA proportional and linearized to the process input. This linearized signal can be used for remote measurement and indication. For the dual input model PTX-3000-T, two independent 4-20mA signals are available on three wires.

For interface with PLC or DCS or with any other process controller – the measured and displayed analog input is converted for digital serial communication on RS485 bus with MODBUS RTU protocol in slave mode.

Advantage of RS485 interface: Providing the feature of RS 485 digital serial interface is advantageous, since the number of wires coming from the various sensors can be avoided and instead, only two wires can be used to interface multiple such PTX-3000 on serial port. For example, for a large heating system incorporating 16 thermocouples, under conventional method 16 dual core compensating cables will run from the heating system to the control panel, where as in case of RS485 interface, only two wires will run from the system to the control panel. Another advantage of RS485 interface is that, when to be interfaced with PLC – the additional analogue module is not required, since most PLC accepts RS485 interface on MODBUS RTU protocol.

Features :

• Microcontroller based design.

• Universal industrial input (user selectable).

• Isolated 4-20mA proportional and linearized for the selected input.

• RS-485 MODBUS RTU serial interface.

• Bright red LED display.

• IP 65 ABS plastic enclosure.

• Operates on 18 to 36VDC.

Technical specifications :

| Input Sensor | J,K,R,S,B thermocouple or RTD (Pt-100) or mV, mA signal (Input type not listed here can also be provided) |

| Range | Full range of the selected input - desired measuring range can be chosen from range selection table in PDF. |

| Accuracy | Software linearized to +/-1 oC for thermocouple input and |

| Power Supply | 24VDC +/- 10% @ 150mA |

| Current Output 1 | 4-20mA proportional to the specified range of the user selected input. (12 bit resolution). – 2 wire |

| Current Output 2 | 4-20mA proportional to the specified range of the second specified input. (12 bit resolution). For PTX-3000-T |

| Digital Serial Output | Isolated 2 wire RS485 on MODBUS RTU protocol in SLAVE mode |

| Isolation | 4-20mA and RS485 outputs are isolated from DC Power supply. |

| Loop Resistance | RLmax = 400 Ohms - for each output. |

| Display | 4 digit - 0.3” red seven segment LED . |

| Connection | 2 or 3 wire for sensor input, 2 wire for DC supply and 2 x 4-20mA for current outputs, 2 wire for RS-485 outputs. |

| Cable Entry | Through suitable size gland for supply and input/output. |

Enclosure (Size) |

ABS plastic IP-65 (120 x 80 x 55) mm. |

![]()