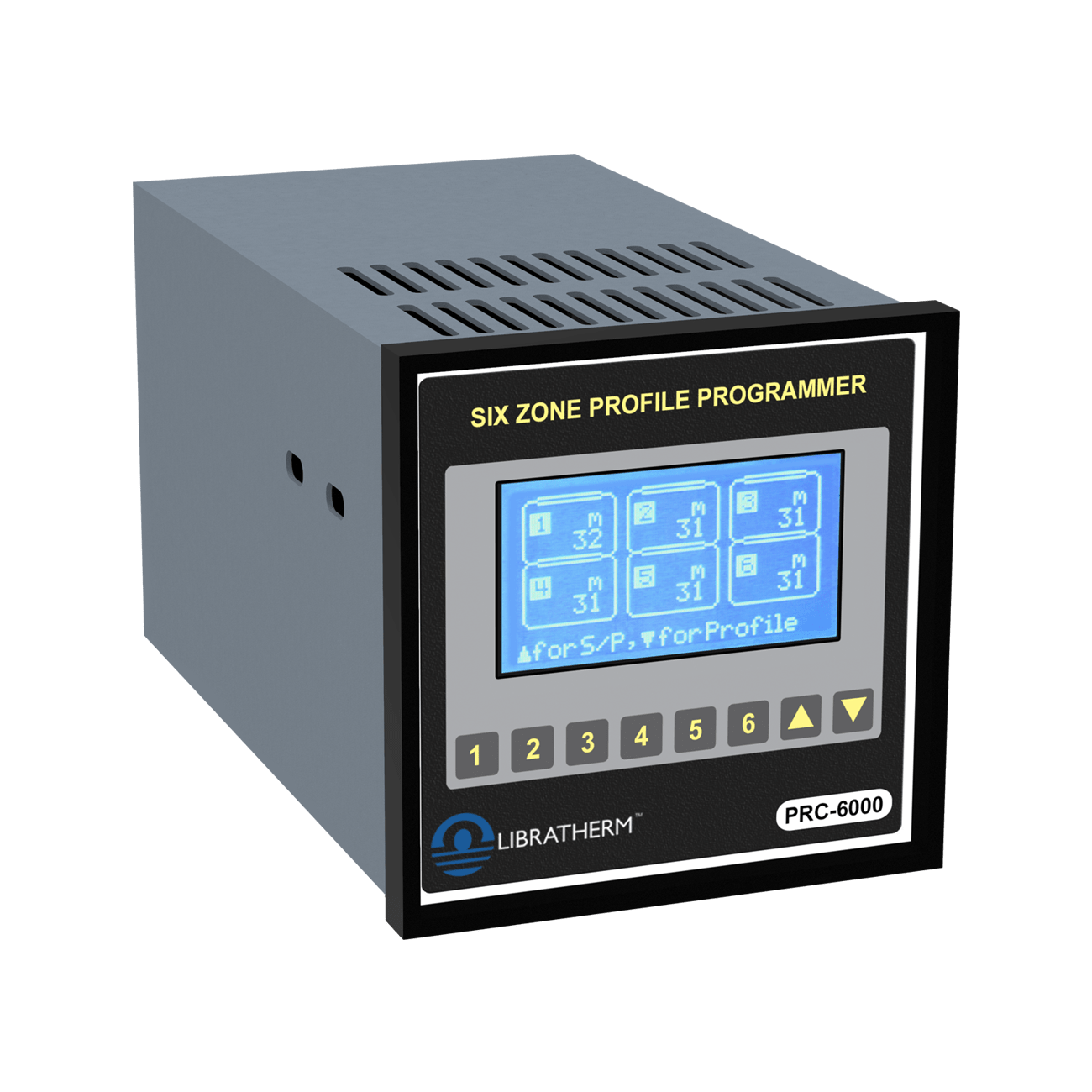

6 Zone Ramp/Soak PWHT Temperature Controller – PRC-6000

Product Description :

PRC-489 Six input/output and six independent 4 steps profile programmer cum temperature controller for SR/PWHT Cycle.

Size : 96 x 96 x 160

PRC-6000-PNL Ready to use panel with input/output connections for SR/PWHT Cycle.

Size 350 x 250 x 325

Technical Specification

| Parameters | Description |

|---|---|

| Input | Cr/Al – K type thermocouple – grounded or ungrounded |

| Range | 0 to 1200 °C. |

| Resolution | 1 °C/1 °F for thermocouple input. |

| (User selectable unit of measurement °C or °F) | |

| Indicating Accuracy | +/- 1 °C for Thermocouple throughout the range |

| Display | 4 digit 0.25” Red 7-segment display for process variable. |

| 4 digit 0.25” Green 7-segment display for set value and PID parameters | |

| Output Indication | Front Panel LED indications for SSR output. % Control Output and for Alarm status and status of heating, cooling, and soaking |

| Control Algorithm | PID or ON/OFF selectable (when specified for switching output). |

| Open sensor indication | OPEn flashes on the display and control action are turned off or control can be transferred to manual mode and power can be adjusted through keyboard from 0 to 100%. |

| Tuning | Manual tuning of PID values. |

| PID Values | Proportional Band (P)= 0.0 to 100.0% of Span, |

| Integral (I)= 0.00 to 5.00 resets/minute, | |

| Derivative (D) = 0.00 to 10.00miutes, Cycle Time = 2 to 100 seconds. | |

| Hysterisis = 0 to 100 °C, Soft start or Ramp time (rt) = 2 to 99 seconds | |

| Power Limit (PL) = 0 to 100%. Deviation Hold (dHLd) = 0 to 50oC (0= no auto hold) For 1st preheating ramp, dHLd will not be applicable. | |

| Settings | Using the front panel feather touch (tactile) keyboard to set various parameters. |

| Control Output | DC pulse to drive external SSR b) Triac(AC switch) 2A @ 250VAC to drive an external relay or contactor coil and c) 4-20mA/0-5VDC to drive external thyristor power regulators. |

| Ramp/Soak Steps | 1 to 16 Steps |

| Ramp rate (Pr) | 1 °C/hour to 1200oC/hour (for K type t/c) |

| Soak Temperature (PL) | Programmable for each step in the full range of the specified input |

| Soaking Time (Pd) | 1 minute to 99 Hour. 59Min. |

| Program Hold Facility(dHLd) | Manual Hold or Auto Hold (Hold back feature for guaranteed Ramp/Soak facility). Deviation holds effective from 2nd ramp onwards. |

| Alarm Output | Relay Output with programmable hysteresis- can be used as High or Low Alarms or End of Profile relay. |

| Master / Slave | User programmable as Master or Slave for multi-zone control |

| Serial Communication (Optional) | Optically isolated 2 wire RS485 -Modbus RTU protocol – for both master controller and slave controller with programmable slave ID. |

| Supply | (90-250)VAC, 50/60 Hz |

| Size / Panel Cutout | 48w x 96h x 110d mm. / 45 x 92 mm. +/- 0.5 mm. |

| Enclosure | ABS plastic with polycarbonate front graphic. |